Hydraulic and pneumatic power tongs include drill pipe tongs, casing tongs and tubing tongs. With all types, your crew needs safe, efficient, reliable performance with a good torque-to-weight ratio.

Here’s a little more info about different rig tongs:

Drill Pipe Tongs: Used to screw industrial tubular together to form a drill string and its components, which make the drill bit turn at the bottom of the wellbore.

The drill string includes the drill pipe, bottom hole assembly, a kelly or top drive motor and any other in-hole equipment used during drilling operations. These tongs should be effective at lowering drill time and reducing costs. They typically come in sizes 2.36 to 10 inches.

Casing Tongs: Used to make or break casing tubulars placed in the drill hole to maintain the well opening. They can handle lightweight casing and have torques ranging from 15,000 to 200,000 foot-pounds. Typical sizes are from 5.5 to 36 feet.

Tubing Tongs: Holds and rotates tubulars used for oil and gas extraction. They are ruggedly designed to perform at higher torques required to break premium connections. Like casing tongs, they also come in a variety of torque specifications.

Quality tongs improve the efficiency and safety of drill floor operations. These large-capacity, self-locking wrenches apply torque where needed when making up or breaking out tubing. Just like a plumber using opposing pipe wrenches, rig tongs are always used in opposing pairs. One set of tongs is tied off with a cable or chain to the derrick, and the other is pulled with mechanical catheads.

Tongs used during makeup (tightening) operations are called makeup tongs; the ones used during breakout (the process of unscrewing drill string components) are called breakout tongs. Depending on the specific application, there are also riser tongs, chisel tongs, rotary tongs and manual tongs.

During makeup operations, the “lead tongs” (pronounced “leed”) are the pipe tongs suspended in the derrick or mast and operated by a chain or a wire rope connected to the makeup cathead or the breakout cathead.

The tong pull line is a length of wire rope with one end connected to the end of the tongs and the other to the cathead on the drawworks. When the driller actuates the cathead, it takes in the tong line and exerts force on the tong to either make up or break out drill pipe.

The lead-tong hand is the crew member operating the lead tongs when drill pipe and drill collars are being handled and pipe is going into the hole. For breakout operations, breakout tongs are used to start unscrew sections of pipe from one another, primarily drill pipe coming out of the hole.

Tong dies play a key part in helping power tongs or manual tongs grip tool joints. Running in or pulling out tubular at oil rigs, the tool joints are adjusted with power tongs or manual tongs.

Dies are pieces of serrated steel installed in the tongs that grip the tool joint of drill pipe when the tongs are latched onto the pipe. Tong dies are made of alloy steel, and their hardened surfaces resist wear. The inner ductile core minimizes the shock of impact and torque.

Calculating Torque

During makeup, how much force should be applied to the tongs to get the torque needed? The formula to determine torque value when you use the rig tong to make-up the connection is this:

Torque=Force x the Length of the tong

Where:

- Torque is measured in feet/pounds

- Force is measured in pounds

- Length of the tong is measured in feet

- Force is perpendicular to the length of the tong

Keystone Tubing Tongs

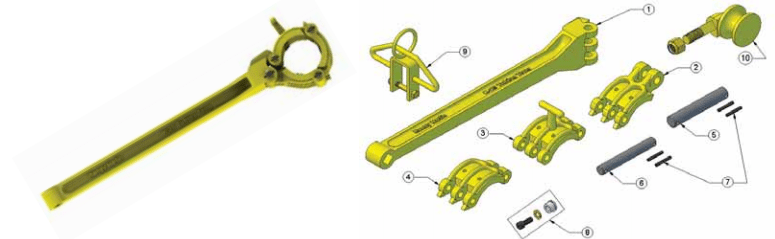

Keystone’s K-Series tubing tongs are pull-tested and complete documentation is available with each purchase. Designed for heavy-duty service of tubing 1.050 to 3.875-inch OD, they offer a wraparound design with approximately a 300-degree die contact to prevent crushing of thin wall tubing.

The KET K-25 tubing tong has a wide range (1.050 to 2.875-inch) and can be used by hand or with a rope block and cat line during makeup and breakout operations. They are made of high alloy steel, heat-treated for strength and wear, and then tested. The KET K-25 tubing tong also has a 2,000 foot/lb maximum torque rating. The K-30 tong has a 5,000 foot/lb maximum torque rating and a 1.660 to 3.875-inch range.

We also carry tong die drivers and tong safety handles.

Why Keystone?

Did you know that most new Keystone customers end up buying from us a second or third time? Why is that? We have knowledgeable sales staff who give you quick turnaround on quotes. We deliver tools on time. We have the quality needed at a price that is competitive with the bigger operations who won’t return your calls. Get in touch today and discover the Keystone difference.