Oil and gas elevators are easily some of the most stressed components in the drilling industry. They require regular, careful inspection to ensure proper functionality. Oil rigs usually carry sets of elevators and spare duplicates just in case. And for good reason. Whenever an elevator fails, all operations stop. Nothing can be done until it’s fixed or replaced.

Even so, oil and gas elevators regularly break, fail, or are just worn out after repeated use. When you think about the pressures, forces and conditions they’re constantly subject to, this is hardly surprising. Many businesses opt to buy new elevators whenever old elevators fail, which adds up over the course of a year. Expenses aside, constantly wearing out old elevators only to buy new ones and repeat the process is wasteful. That’s why elevator remanufacturing is the best option.

In 1995, the United States Environmental Protection Agency (EPA) implemented its Comprehensive Procurement Guideline (CPG) to promote waste reduction and resource conservation. Remanufacturing is defined as the rebuilding of products from reused, repaired, or new parts to original manufactured product specifications under CPG requirements. In other words, remanufactured products are functionally identical to what could be expected from new products.

It’s important to note that the term “remanufacture” is not synonymous with the terms “reuse,” “repair,” “refurbish” or “recycle.” A remanufactured product exceeds the quality of a reused, repaired, refurbished or recycled product. When new, superior parts are used in remanufacturing, the remanufactured product may actually exceed the capabilities of the original product, as often happens in the automotive industry.

The oil and gas industry is just one of many that remanufacture products. When you think about it, oilfield tools are designed to be easily taken apart, which makes them perfectly suited for remanufacturing. And elevators, one of the industry’s most highly-stressed products, are also one of its most commonly remanufactured components.

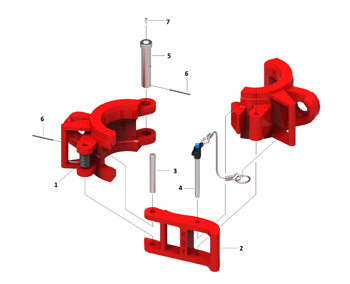

The process is simple. Old elevators are taken apart piece by piece. The parts are refurbished and then put back into inventory. Finally, whenever a remanufactured elevator reaches the top of the production queue, those refurbished parts are reassembled along with new parts to create an elevator functionally identical to a brand new one. But at much cheaper cost.

Keystone Energy Tools has over 30 years of experience manufacturing elevators, and we use that experience to remanufacture and recertify oilfield tools without identity loss. Our remanufactured “G” series, “Y” series and single joint elevators are just as good as original productions, but much more affordable.

If you have old, worn-out elevators you would like to sell, or if you want to buy our remanufactured elevators, Keystone Energy Tools has the solution for your business. Don’t believe us? If you want to see our elevators in action, our load testing facility is available for all elevators and spiders.