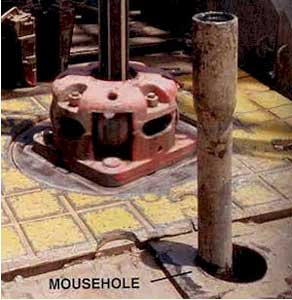

The mousehole is the area on the drilling rig where the next joint of drilling pipe is stored. This is located between the rotary table and vee-door, and is usually fitted with a casing and bottom. Rotating mouseholes, introduced in the early 1990s, have helped cut the time and labor dedicated to adding joints to the drillstring. In this article, we will discuss standard mouseholes, how rotating mouseholes are made, and how they contribute to the overall drilling process.

Rotating mouseholes can also make drilling safer for the crew.

The device automatically rotates the tubulars underneath the rig floor. This eliminates the need for someone to turn the stand inside the derrick. The rotating mousehole is also installed beneath the rig floor. As long as it’s covered when not in use, it’s out of the way of workers, meaning there’s one less obstacle to work around.

Finally, worker safety is reduced simply due to less exposure to the pipe connection process.