We make a Baker®-style drill pipe float valve that is actually better than the original. For example, we use a better quality spring and better materials through out. Inconel® or stainless steel springs come standard on all Keystone valves and are significantly more resistant to corrosion when compared to standard service springs provided by most other manufacturers.

Another benefit? Keystone valves come with certifications (traceability).

“We started stenciling each float valve with an independent serial number and a work order so we can trace the origin,” Ramey says. Keystone also stencils inserts with heat codes and material codes so they can trace that insert back to where they bought the material.

“I don’t think anybody else is doing traceability of inserts and float valves,” Ramey says. “We offer documentation and traceability on each insert and float valve that we manufacture.”

Keystone also offers “white label” (private label) on inserts & float valves, only available for quantity orders of float valves.

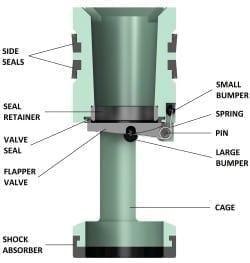

- All Flappers are investment cast and then case hardened for wear resistance.

- Elastomers available are Nitrile Butadiene (NBR /Buna N), Hydrogen Nitrile Butadiene (HNBR), and Viton® (Fluoroelastomer / FKM).

- All KET Float Valves, baffle plates, and valve pullers are interchangeable with the Baker® Style Model F, and Baker® Style Model G Float Valves.

Being the “little guy” enables Keystone to give the best service and level of professionalism in the industry.

One of the big advantages we have is it’s a lot easier to do business with us. A customer calls us at 10 in the morning or 2 in the afternoon, it’s going to get shipped the same day. You call our competition, you might not get a phone call back for two days.

Keystone can be trusted to get you the right parts on time.