It can never be said enough that drilling safety should be the top priority on any rig. Hazardous conditions can lead to worker injury and longer operation times. One example is the handling of drilling fluids. As drill pipe is connected, leaking fluids can spill on the drill floor, putting workers at risk for slipping while handling other equipment.

Mud buckets address these risks. They are used to capture and redirect drilling fluids away from operations. In this post, we will discuss how the mud bucket is used, starting with the traditional model. We will then give an overview on how models have improved, along with some complementary tools.

What is a mud bucket?

The standard mud bucket clamps around the pin and box ends of the drill pipe. When one strand of pipe is unscrewed, the mud bucket encloses this loose end to capture the fluids. These fluids are then redirected through a hose to the mud pit or fluid line. In this respect, mud buckets contribute to an operation’s fluids and solids control system.

Risks of Mud Buckets and Improvements Today

While mud buckets increase safety on any drilling rig, the traditional model does have its drawbacks. Yet advances in drilling technology have led to a range of improvements on the mud bucket, some approaching the tool in entirely new ways.

·Efficiency: The time needed to change seals can drastically affect the operation’s overall project time. To address this, some companies have adjusted their seals to allow for quicker change times. Others have focused on creating lighter mud buckets for easier handling.

·Pinch Points: A main concern during drilling is worker exposure to pinch points. These are present when two objects come in contact with each other without guards, putting the worker at risk of getting caught. Regarding mud buckets, this would include the worker’s arm getting caught as the bucket clamps around a pipe. Companies have approached this issue in different ways, from adding safety bars to adjusting the bucket’s design to allow for more space between the workers and the bucket.

·Self-supporting Mud Buckets: These models require little setup, with the only adjustment needed on the drill floor being a hole to weld the outlet socket. This type of mud bucket also removes several issues associated with the standard model. One swing is needed to lock the bucket into position, reducing the number of “pinch points” workers are exposed to. This model doesn’t require equipment like cables or discharge hoses, resulting in a more open drill floor.

Other Tools to Help with Mud Buckets

While mud buckets are great to include in any operation, the tools below can further assist in the fluid cleaning process or help with the mud bucket itself.

·Vacuums: Depending on the type of mud bucket used in the operation, it might be beneficial to have other equipment help control excess fluids. The mud bucket often comes in contact with other equipment such as tongs. This could lead to the mud bucket being banged or dented, affecting the bucket’s ability to close around the pipe. As their name suggests, vacuums are used to wipe any fluids on the drill floor to prevent any slipping.

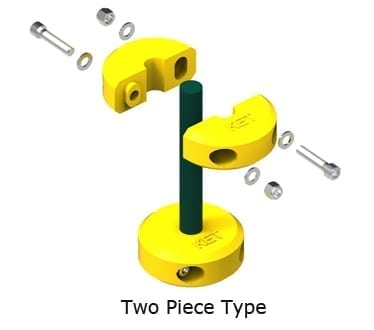

·Tong Safety Handles: Every operation can benefit from additional accessories to improve worker safety. Available in one or two pieces, Keystone provides these to protect workers’ hands when using mud buckets.

Mud buckets have become a standard on drilling rigs; their contribution to worker safety cannot be overlooked. While oilfield technology is always moving forward, the mud bucket is one prime example to show how far it’s come already.